DWSIM Simulator is a Steady-State Chemical Process Simulator, featuring:

- Offline functionality: no need to connect to online databases or servers, DWSIM runs completely offline on your device, wherever you are!

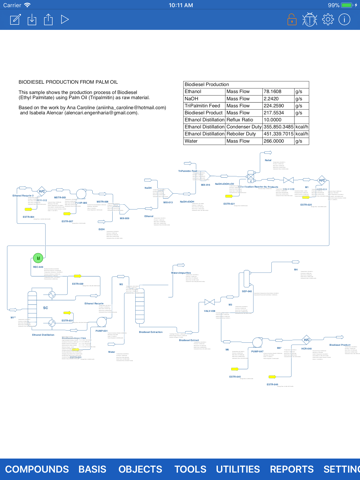

- Touch-enabled Process Flowsheet Diagram (PFD) Drawing Interface: A hardware-accelerated PFD interface with touch support allows Chemical Engineers to build complex process models in a few minutes

- VLE/VLLE/SVLE calculations using Equation of State and Activity Coefficient models: calculate fluid properties and phase distribution with advanced thermodynamic models

- Compound database with extensive data for more than 1500 compounds

- Rigorous Thermodynamic Models*: Peng-Robinson EOS, Soave-Redlich-Kwong EOS, Lee-Kesler-Plöcker, Chao-Seader, Modified UNIFAC (Dortmund), UNIQUAC, NRTL, Raoults Law and IAPWS-IF97 Steam Tables

- Thermophysical state (phase) properties: Enthalpy, Entropy, Internal Energy, Gibbs and Helmholtz Free Energies, Compressibility Factor, Isothermal Compressibility, Bulk Modulus, Speed of Sound, Joule-Thomson Expansion Coefficient, Density, Molecular Weight, Heat Capacity, Thermal Conductivity and Viscosity

- Single-compound properties: Critical Parameters, Acentric Factor, Chemical formula, Structure formula, CAS Registry Number, Boiling Point Temperature, Vapor Pressure, Heat of Vaporization, Ideal gas Enthalpy, Ideal gas Enthalpy of Formation at 25 C, Ideal Gas Gibbs Free Energy of Formation at 25 C, Ideal Gas Entropy, Heat Capacity Cp, Ideal Gas Heat Capacity, Liquid Heat Capacity, Solid Heat Capacity, Heat Capacity Cv, Liquid Viscosity, Vapor Viscosity, Liquid Thermal Conductivity, Vapor Thermal Conductivity, Solid Density, Liquid Density and Molecular Weight

- Comprehensive Unit Operation Model set*, including Mixer, Splitter, Separator, Pump, Compressor, Expander, Heater, Cooler, Valve, Shortcut Column, Heat Exchanger, Component Separator, Pipe Segment, Rigorous Distillation and Absorption Columns

- Support for Chemical Reactions and Reactors*: DWSIM features support for Conversion, Equilibrium and Kinetic reactions, together with their respective Reactor models

- Flowsheet Parametric Studies: Use the Sensitivity Analysis Tool to run automated parametric studies on your process model; The Flowsheet Optimizer tool can bring the simulation to an optimum state according to user-defined criteria; The Calculator tool can read flowsheet variables, perform math operations on them and write the results back to the flowsheet

- Petroleum Characterization: Bulk C7+ and TBP Distillation Curve characterization tools enables creation of pseudocompounds to simulate petroleum processing facilities

- Parallel multicore CPU calculation engine: a fast and reliable flowsheet solver takes advantage of the multicore CPUs on modern mobile devices

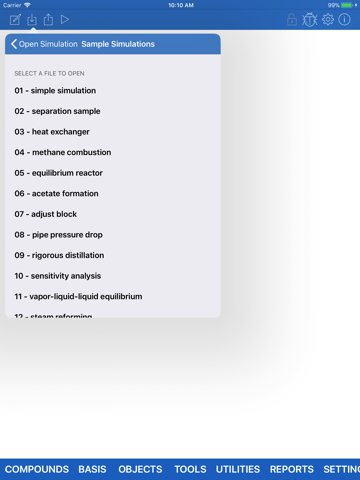

- Save/Load XML simulation files on the device or in the cloud

- Export simulation results to PDF and Text documents

* Some items are available through in-app purchases

ABOUT CHEMICAL PROCESS SIMULATION

Chemical Process Simulation is a model-based representation of chemical, physical, biological, and other technical processes and unit operations in software. Basic prerequisites are a thorough knowledge of chemical and physical properties of pure components and mixtures, of reactions, and of mathematical models which, in combination, allow the calculation of a process in a computing device.

Process simulation software describes processes in flow diagrams where unit operations are positioned and connected by product or educt streams. The software has to solve the mass and energy balance to find a stable operating point. The goal of a process simulation is to find optimal conditions for a process.